Measures following the Shutdown of the Krško Nuclear Power Plant

All decisions before and during the shutdown of the Krško plant were based on the principle of conservative decision-making and a high-level safety culture. Upon the indication of a leak in the containment building, we decided to preventively shut down the power plant; the operations team began a gradual reduction of power on Thursday evening, 5 October. On Friday morning, the reactor was shut down and the power plant in the so-called hot standby. Teams entered the containment building to determine the location of the leak. To pinpoint the location, we cooled down the plant to ensure safe working conditions. At the end of the week, we confirmed the location of the leak on the small pipeline of the reactor connection system.

The amount of leakage was within operating limits. All water was collected in containment systems and will be processed with an evaporator according to established procedures.

Cause Analysis and Preparation of an Action Plan to Eliminate the Deviation

Today there is no pipe leakage in the state of cold shutdown of the power plant. There is a hole the size of a sewing needle at the weld of the reducing part of the piping connection system of the primary circuit, one meter from the penetration into the reactor vessel. Diagnostics, destructive and non-destructive analyses of pipelines, analytical support studies, and maybe licensing for repair methods will be required. In doing so, Krško NPP constantly cooperates with domestic and international institutions and companies.

At present, considering foreign experience, several possible causes of leakage have been identified and are being analysed: a hidden defect in the welding process, a defect in the material, thermal fatigue of the material, stress corrosion, and mechanical stress. We are already determining the actions that would be necessary to eliminate all possible causes of the leak. After transferring fuel from the reactor core to the Spent Fuel Pool, the pipeline will be ultrasonically inspected from the inside and outside. We expect to discover the cause of the leak through these inspections.

At the Krško NPP, our goal is to complete all the necessary diagnostics and analyses in about a month. We know that this will be a challenge for employees, institutions, and partner companies. It is still too early to predict the date of synchronization of the power plant with the grid. We want to solve the problem professionally and with high quality to continue along the planned path of long-term safe and stable plant operation.

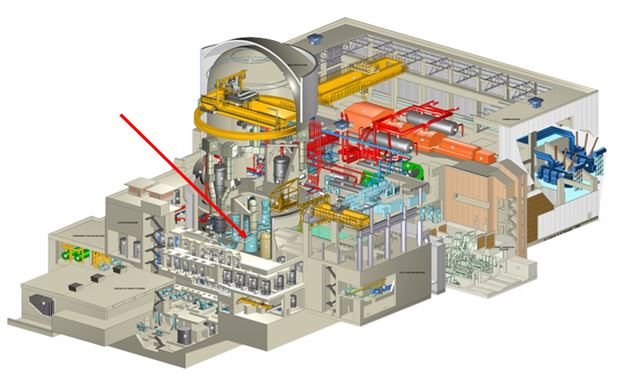

Illustration

Cross-section of the power plant with a leak-tight containment consisting of an inner pressure steel shell and an outer reinforced concrete protective building. It contains the components of the primary circuit; the reactor vessel is marked with an arrow. The personnel airlock and equipment hatch are equipped with airtight transition chambers and double doors; the penetrations for pipelines and cables are double-sealed.

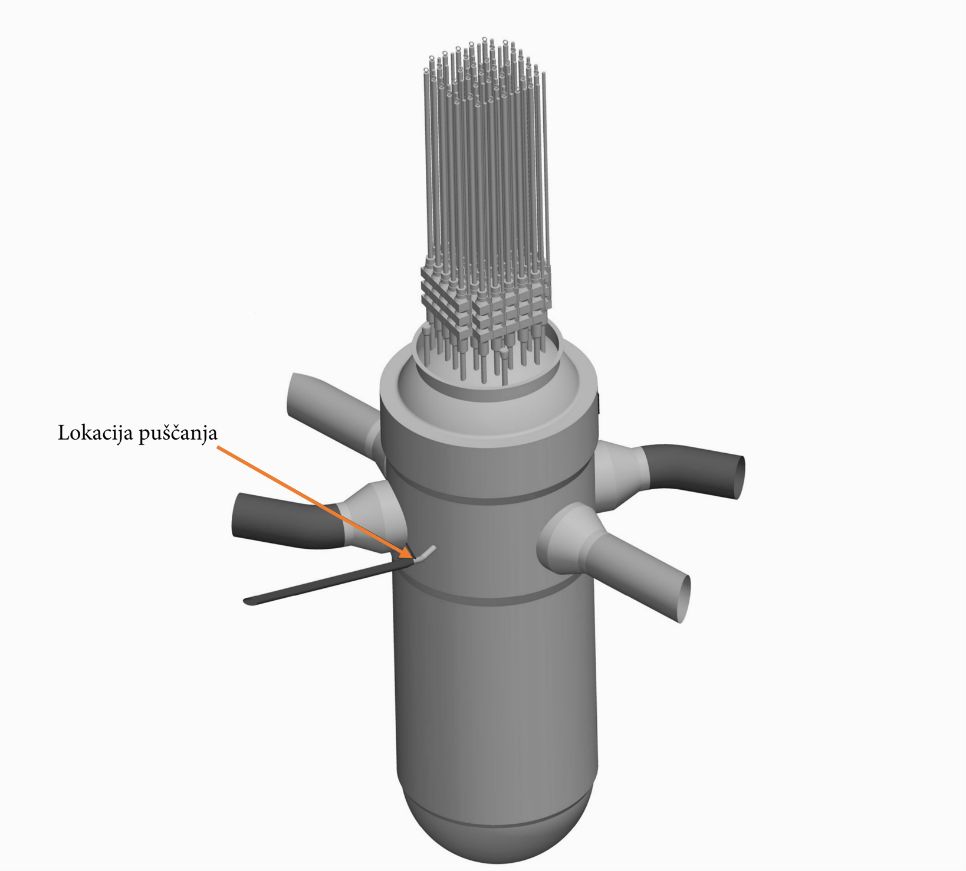

A display of the reactor vessel, which is 11.9 meters high. On top of the reactor head covering the vessel are the control rod guides. In the middle, there are four pipelines or two loops through which hot water flows between the reactor vessel and the U-tube bundles in the steam generators; the steam generators are heat exchangers and separate the primary and secondary circuits of the power plant. The average water temperature in the primary circuit when the reactor is operating at full power is 305 ˚C, and the pressure is 15.4 MPa (154 bar).

On the smaller pipeline of the connection system of the primary circuit, the location of the leak is marked with an arrow in the picture.

Photograph of part of the smaller 11.4 cm diameter primary circuit connection system piping. The left arrow shows the location of the leak.